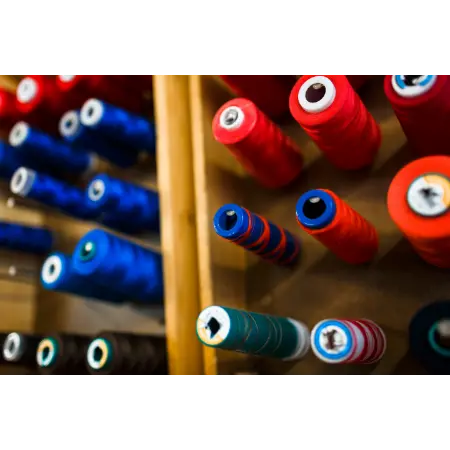

The use of polypropylene yarn is becoming widespread in the textile industry due to its durability and lightweight structure. Additionally, with its high strength values, it is preferred in many areas, from industrial fabrics to home textiles. Therefore, it can meet both technical and aesthetic expectations. In this case, its resistance to water and chemicals ensures long-lasting use. Furthermore, its recyclable structure supports environmentally friendly production and contributes to sustainability. In addition, polypropylene yarns offer a wide range of color options with their easy-to-dye properties. Therefore, they can be used in carpets, upholstery fabrics, sportswear, and medical textiles. Moreover, its low moisture absorption provides quick-drying properties. This enables comfortable and practical use. Thus, the use of polypropylene yarn is attractive to manufacturers in terms of both cost advantage and performance. Furthermore, its durability reduces the risk of deformation and ensures consistent quality.

Contents

- Polypropylene Yarn Manufacturers

- Polypropylene Yarn Raw Material

- Where is Polypropylene Yarn Used?

- Companies Producing Polypropylene Yarn

- Conclusion

- Frequently Asked Questions

Polypropylene Yarn Manufacturers

Polypropylene yarn manufacturers produce in modern facilities equipped with advanced technologies. They also offer a wide range of solutions to the textile industry with high-strength yarn varieties. For this reason, they are frequently preferred in carpets, upholstery fabrics, sportswear, and industrial textiles. In this case, manufacturers can produce for both domestic and export markets. Moreover, R&D investments enable the development of more durable yarn types. Thus, quality, efficiency, and sustainability are ensured in production, while polypropylene yarn manufacturers adopt eco-friendly techniques. Therefore, production policies that reduce the carbon footprint and support recyclable products are implemented. In this way, both economic and ecological solutions can be developed for the modern textile industry.

Polypropylene Yarn Raw Material

Polypropylene yarn raw material is a strong thermoplastic obtained from petroleum-based polymers. Additionally, its low-density structure enables the production of lightweight yet extremely durable products. Therefore, it is possible to obtain energy-efficient, economical, and long-lasting textile products. In this case, manufacturers can create a production process that reduces costs while increasing performance. Furthermore, this raw material exhibits high resistance to water, chemicals, and friction. Thus, it can be safely used in outdoor textiles and industrial fabrics. Therefore, it can be integrated with environmentally friendly and energy-saving production methods.

Where is Polypropylene Yarn Used?

Polypropylene yarn finds wide application in various industries thanks to its versatile properties. It is also preferred in the carpet, sportswear, upholstery fabric, home textiles, and medical textiles sectors. Therefore, it offers significant advantages to manufacturers with both its durability and low cost. In this case, it provides long-lasting solutions in industrial products with its water and chemical resistant structure. Moreover, its low moisture absorption allows for the production of quick-drying and hygienic textile products. This enables the development of comfortable, lightweight, and practical products. In addition, polypropylene yarn is widely used in outdoor textiles and technical fabrics. Therefore, it is an ideal choice for manufacturers seeking both aesthetic and functional solutions.

Companies Producing Polypropylene Yarn

Polypropylene yarn manufacturers have modern production infrastructure that meets global quality standards. They can also develop special yarn types according to customer demands, responding to the needs of different sectors. Therefore, they are positioned as reliable suppliers in the textile, automotive, medical, and industrial fields. In this case, processes are optimized with high production capacity and advanced technology machines. Furthermore, the strength and color fastness of the products are continuously monitored through quality control systems. This ensures continuity in production and customer satisfaction. Consequently, energy-saving, waste-reducing, and environmentally conscious systems are utilized. This enables manufacturers to make a difference both economically and environmentally.

Conclusion

As a result, polypropylene yarn production has become one of the most strategic components of the modern textile industry. Furthermore, thanks to its durability, lightness, and economic production advantage, it is widely used in various sectors. Therefore, it shapes the textile solutions of the future in terms of both performance and sustainability. In this case, manufacturers can offer environmentally friendly and long-lasting products with high quality standards. Furthermore, the use of recyclable raw materials paves the way for green transformation in the industry. Thus, polypropylene yarns provide not only a cost advantage but also environmental responsibility.

Frequently Asked Questions

Where is polypropylene yarn used? It is used in carpets, home textiles, sportswear, and technical fabrics.

What does twisted yarn mean? Twisted yarn is a type of yarn in which the fibers are twisted in a specific direction to increase its strength.

Is polypropylene yarn water-permeable? No, it is liquid-impermeable thanks to its water-repellent properties.

What are the advantages of these yarns? They are lightweight, durable, economical, and long-lasting.

Can polypropylene yarn be dyed? Yes, it can be dyed in any desired color using special techniques.

Is polypropylene yarn heat resistant? Yes, there are types that are resistant to high temperatures.

In which sectors is it most commonly used? It is used in the textile, automotive, medical, and industrial sectors.

At what temperature does polypropylene yarn melt? It generally has a melting point between 160–170°C.

Is polypropylene yarn economical? Yes, it is often preferred by manufacturers due to its cost advantage.

Why should polypropylene yarn be preferred? Because it is one of the most efficient types of yarn in terms of both quality and sustainability.